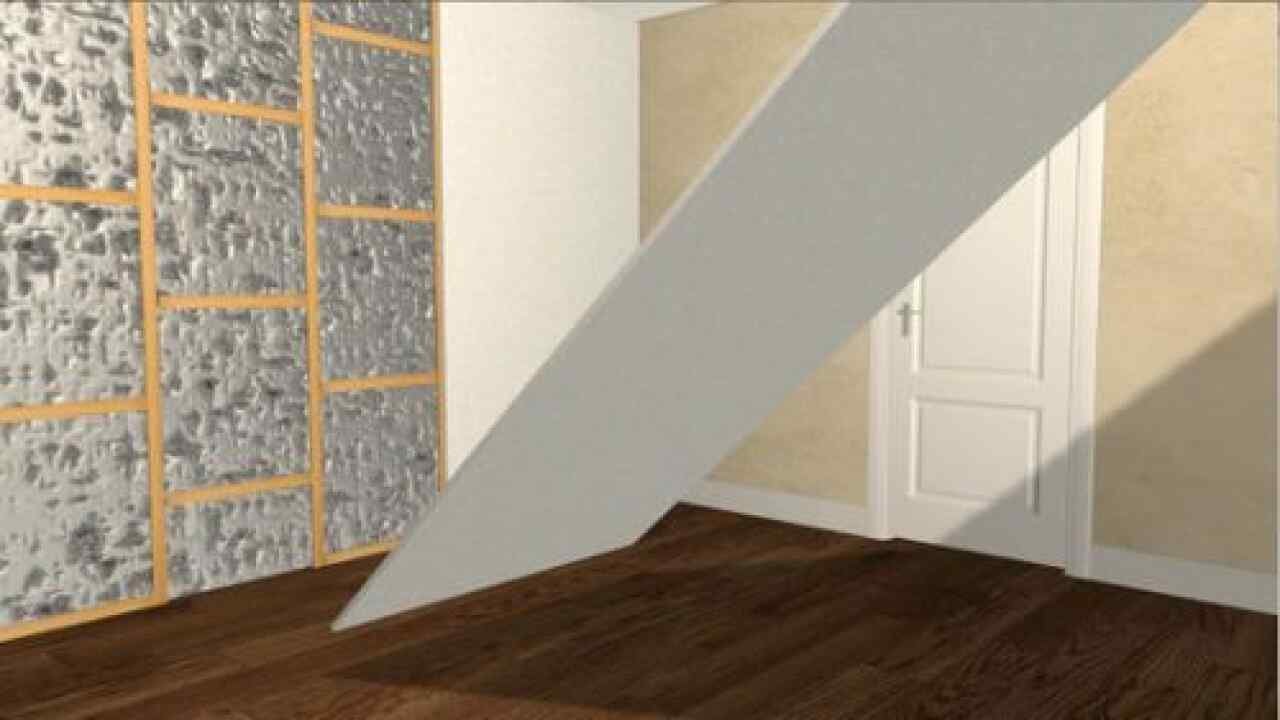

Acoustic insulation comes with a long list of causes and solutions, ranging from people who want a more a home from noisy neighbors to companies needing to reduce the impact of noise on their surroundings, in fact there are countless soundproofing materials to choose from for different uses, some of which are more convenient Or effectiveness from others, the other, which depends largely on the type of noise issued in addition to the source of the noise, the structure of the building, the construction of the wall and a lot of other basic factors, as it has many details that we will discuss in our next article on the site of the specialist for trading and contracting.

sound insulation

To understand soundproofing materials and how they perform it is important to note that sound is a form of energy, sound travels from one source to another, because during the distance it travels it causes vibrations, and when it hits the air or something in its path, these sound waves reach the ears of the receiver to activate the brain.

Sound insulation materials come in all shapes and sizes, it is best for the user to know how and where to create them in order to get the best results. It is also best to consider the quality of a particular soundproofing material they intend to use to achieve the best possible results.

Types of acoustic insulation

Here is a summary of the 10 best soundproofing materials on the market and the best way to use them:

- Vocal membrane:

Pros: Minimum depth of existing structures such as walls and ceiling, Easy to install, Long life.

Cons: Some are a bit heavy with increased mass which in turn provides the opposite effect, and some brands are more expensive.

2 . Acoustic mineral wool:

Pros: Affordable natural materials, resistant to fire and moisture.

Cons: Needs a lot of depth for the substance to work on its own, and protective breathing equipment must be worn because cuts cause shrapnel to seep into the skin, or may be inhaled and irritate the lungs.

- Fiberglass:

Pros: Suitable for different frequency ranges, comes in different thicknesses, and is easy to cut.

Cons: They are known to be a nuisance so wear protective clothing when handling them.

- Flexible channels:

Pros: Relatively easy to install, practical gaps / holes.

Read also: Types of waterproofing and moisture insulation materials and their damages 2022

Cons: Installation takes a lot of time when there is a large area to cover.

- Acoustic Hangers:

Uses: In the construction of walls, ceilings and floors to reduce atmospheric and floor noise.

- Soundproofing Drywall:

Uses: It can be used in any building or room.

Pros: Very effective.

Cons: Excessive weight on impact, expensive option, requires professional installation.

- Density board - OSB, plywood:

OSB or Oriented Strand Board is a durable and versatile construction board, plywood can be used instead; Because the construction is similar to multiple layers of opposing wood fibers that create rigidity and strength while increasing mass and density.

- Acoustic Flooring:

Uses: Important for many types of wood or engineered floors in all residential and commercial buildings.

Advantages: Affordable, easy to install, durable and effective in absorbing sound and moisture.

Cons: It is simply based on audio and will only provide an average level of audio performance.

9 . Soundproof and anti-vibration mats:

Uses: Under or behind appliances or machinery to reduce transmission of noise and vibration.

Pros: Simple and very effective soundproofing solution while machines or appliances are present as a source of sound.

Cons: It is used perfectly with other sound insulation methods to get the best results.

Read also: All types of water stops and how to use it in details

Acoustic sealants:

Uses: Use on walls, ceilings, and any gaps or open spaces such as seams, seal holes, and screw holes.

Pros: Very easy to apply, low price, effective and environmentally friendly.

Cons: The complementary soundproofing option and room will not be sound-isolated.

Share

- Comments